Foam in Place

FOAM IN PLACE: PACKAGING SYSTEM WITH CUSHIONS IN POLYURETHANE FOAM

Foam in Place is the on-demand polyurethane foam cushion system developed by DUNAPACK® thanks to DUNA-Corradini's decennial know-how in the production of rigid foam: its mission has always been ensuring the protection and securing of the most fragile and heavy goods. The FIP range is designed to meet the needs of efficient and safe shipping of products in manufacturing industry and distribution logistics, for foam packaging when necessary and directly at the packaging station.

DUNAPACK® offers its customers a comprehensive, turnkey packaging solution: the FIP System includes the supply of machines for the on-demand production of protective foam, of convenient reels of film bags and formulated systems to produce packaging cushions. Foam in Place foams are available in different densities and expansion speeds designed to specifically meet various types of goods and production/transport needs.

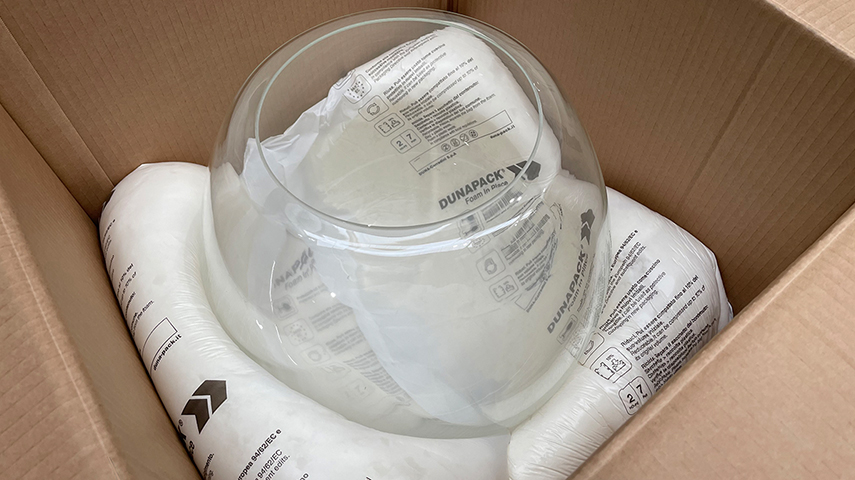

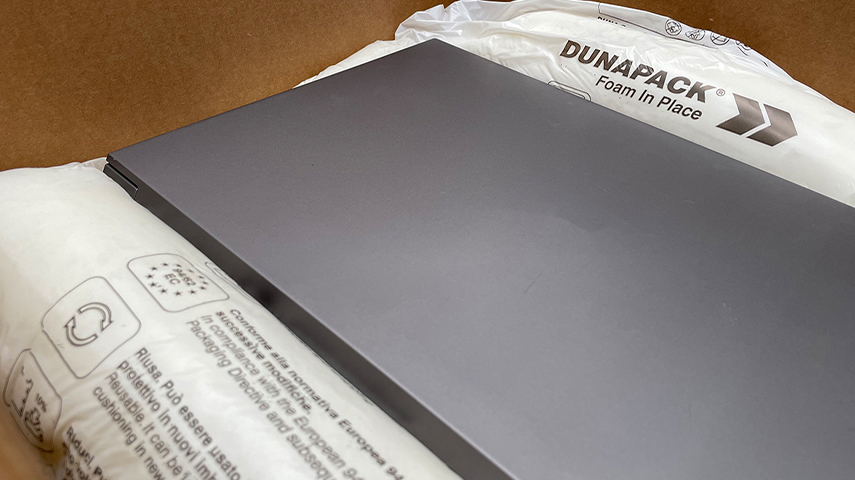

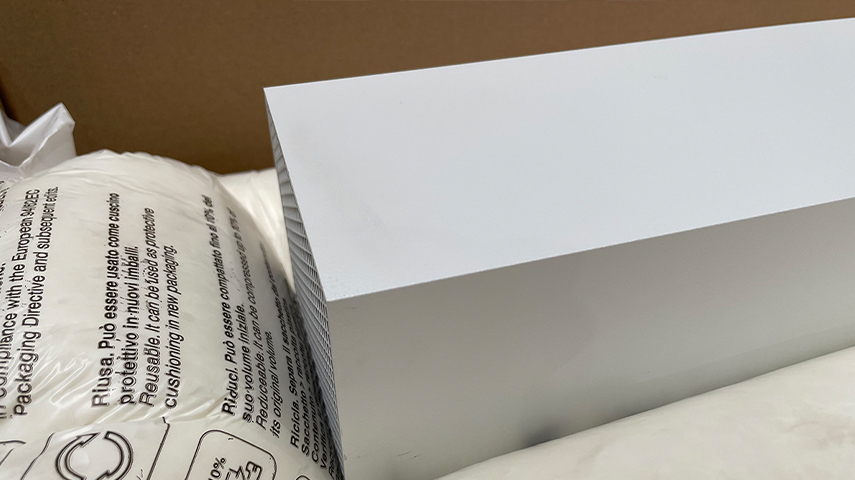

The Foam in Place protective system is based on the technique of encapsulation: the product is gently wrapped in foam, which adapts to the shape of the object as it expands, guaranteeing perfect adhesion, no voids in the secondary packaging and maximum protection against impact and damage from handling and transport.

DUNAPACK's in-house laboratory also provides a fundamental packaging analysis service, to carry out packaging simulations and drop tests on the customer's products to identify the most suitable packaging system for their specific needs, plus a specialized consultancy service to design the perfect integration of the Foam in Place system within the production line or at the end of the customer's plant.

To respond to the growing demand for sustainability in packaging, in 2024 DUNAPACK® has introduced the new DUNAPACK® BIO range of protective cushions made of polyurethane foam containing up to 60% carbon of vegetable origin, capable of reducing the CO2 emissions of packaging by up to 30% with the same protective performance compared to traditional formulation.