PACKAGING

The Foam in Place packaging system offers a wide selection of foams characterized by different densities, expansion capacities and expansion speeds, designed to meet any protection need according to the weight and characteristics of the object, packaging process and transport type.

DUNAPACK® is very attentive to the issue of packaging sustainability and in 2024 has also added the new cushions DUNAPACK® BIO to its traditional formulations: they are made with polyurethane foam containing up to 60% carbon of vegetable origin, designed to reduce the CO2 emissions of packaging by up to 30% for the same protective performance.

DUNAPACK® foams are available in different densities (5, 10 or 20 kg/m3 in the traditional formulation and 6 and 10 kg/m3 in the new BIO version) to guarantee maximum protection for all types of goods, from the most fragile to the heaviest. FIP formulations also have specific expansion capacities (up to 280 times the initial volume) and customized reaction speeds to facilitate operators in the preparation of the packaging system.

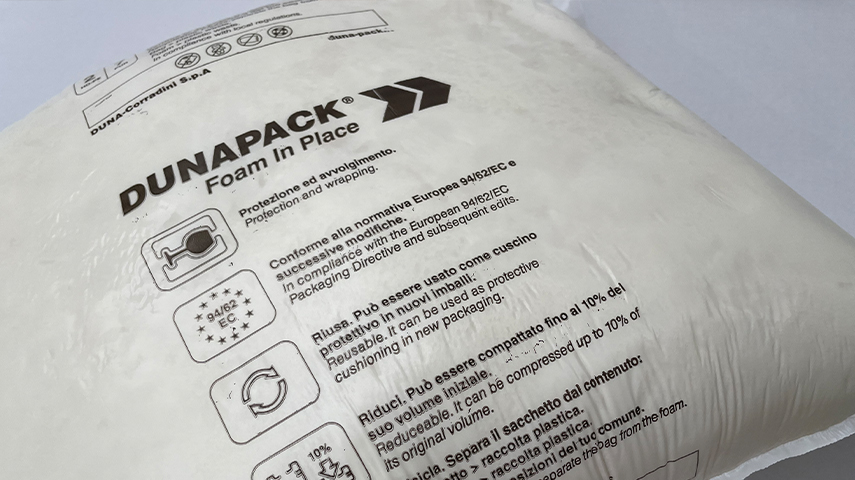

The Foam in Place range is completed by convenient pre-sealed film reels, all made of recyclable polyethylene. Foam dispensing into the bag film allows the finished packaging to be produced on demand.

DUNAPACK® foam cushions can be made with traditional film, available in several practical formats, as well as with pleated film, designed to fully utilize the height of the bag through maximum vertical expansion, or with micro-perforated film, ideal for the protection of items already equipped with primary packaging.

All DUNAPACK® films carry printings with clear indications on their composition and correct handling of the packaging at the end of its life, in compliance with the current environmental labelling regulations (Italian Legislative Decree 116/2020).