Air in Place

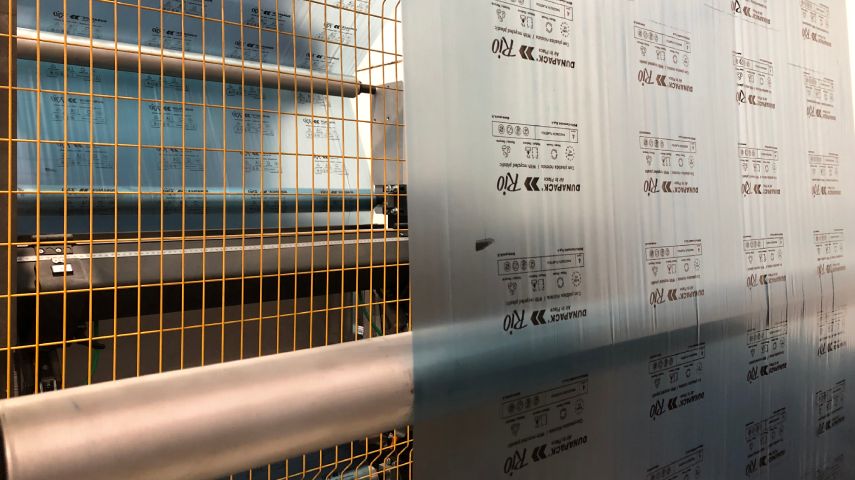

AIR IN PLACE: AIR CUSHIONS PACKAGING SYSTEM

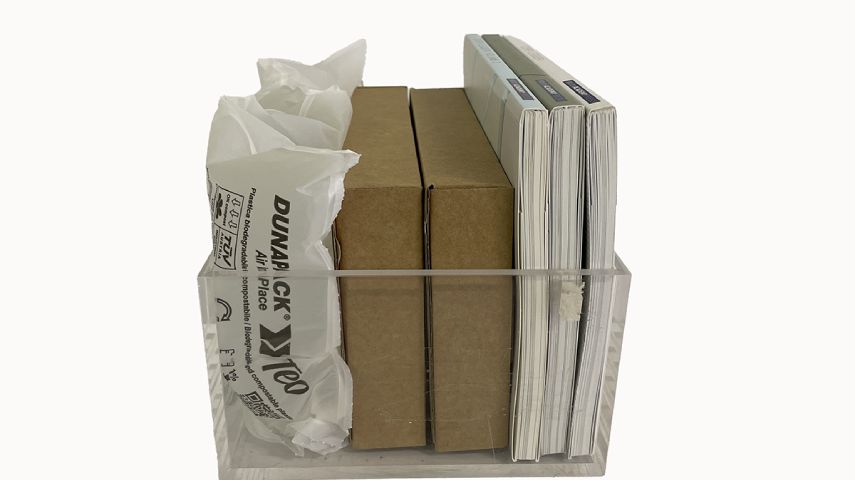

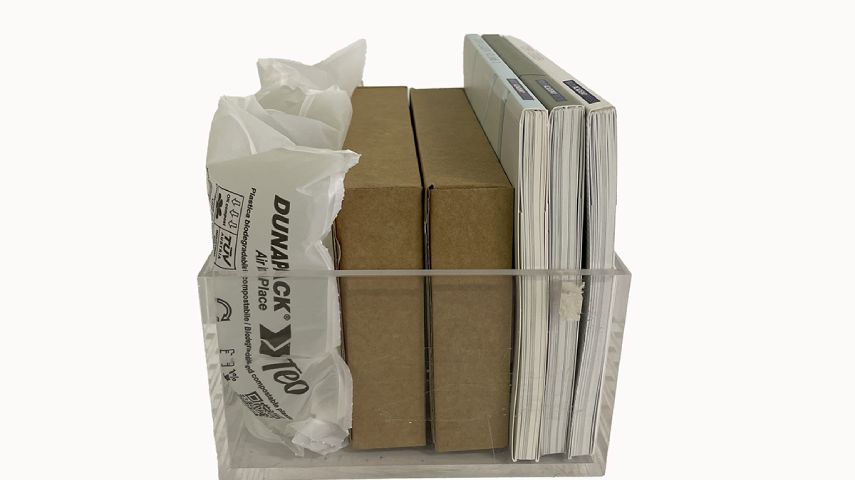

Lightweight, durable and safe, the Air in Place cushions are the ideal on demand packaging for filling voids and securely lock the goods during shipment, preventing the products breakage due to the transmission of transport shocks.

DUNAPACK® offers customers a complete turn-key solutions: the AIP System is composed of a compact machine for on-demand film inflation and air cushion production. The AIP range includes several cushion formats available in 3 different materials to meet different protection needs. The many available accessories and complements are designed to allow perfect integration of the DUNAPACK® system into the customer's production cycle or at the end of the line.

DUNAPACK® provides a specialised consultancy service based on drop tests and comparative cost and performance assessments to support customers in choosing the most suitable packaging for their needs.

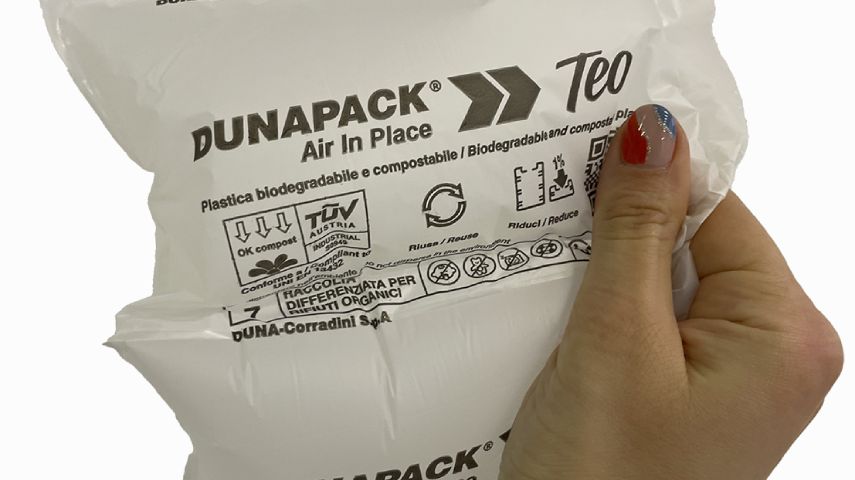

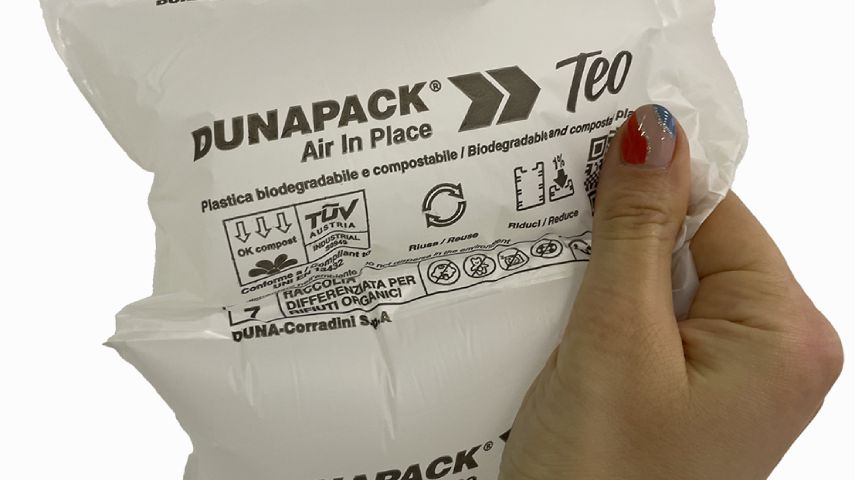

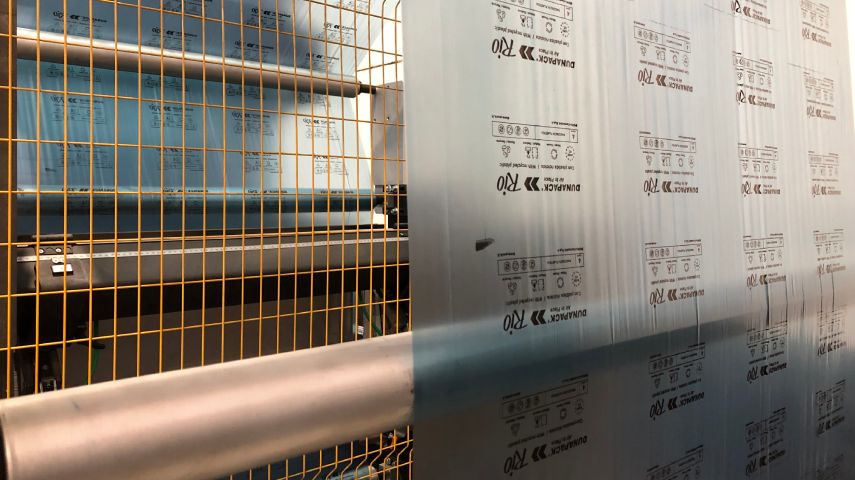

To meet the growing demand for sustainable packaging, DUNAPACK® now offers 3 different types of air cushions. In addition to the traditional high-density polyethylene bags, the AIP range is available in TEO film, made of compostable biodegradable vegetable starch and co-polyester, and already OK COMPOST INDUSTRIAL certified by TÜV Austria according to TÜV Industrial EN 13432 Regulation, and in the new RIO version, made up of 70% recycled plastic - two solutions combining sustainability and maximum performance.

DUNAPACK® research lately focused on reducing the thickness of cushion films aimed at reducing the consumption of raw materials and plastic: early 2024, we completed the revision of the entire Air in Place range adopting new versions with significantly lower thickness at same protective performance.

What’s more the Sustainability Research embrace all aspects of the Air in Place system: to reduce the environmental impact of packaging transport and handling, for instance, DUNAPACK® decided to switch supply method, from the traditional reels to the convenient ready to inflate reams, doubling the supplied bags’ quantity per package. The recent reduction of film thicknesses has further expanded the capacity of each ream, boosting further supply volumes and efficiency.